Cassini Calibration

A controlled access laboratory for post launch calibration, characterization, and diagnostics of the Cassini Plasma Spectrometer (CAPS) and the Cassini Ion & Neutral Mass Spectrometer (INMS).

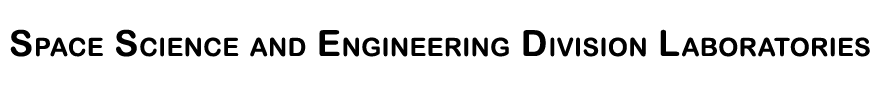

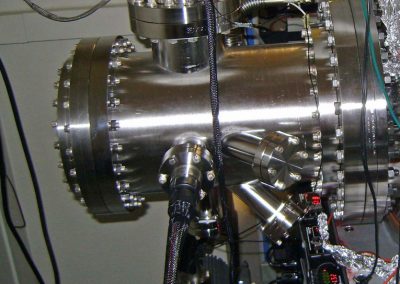

Cassini Plasma Spectrometer (CAPS) Chamber

CAPS Chamber Features:

- Chamber door opens greater than 90 degrees.

- Interior tray drawer permits supported extraction of CAPS instrument & insertion of instruments up to approximately 16” x 16” x 16” cube

- Up to three lab benches available for conversion to ESD operations if necessary.

- Main chamber dimensions: 24” diameter x 24” deep cylinder

- System pumping: 450l/s Seiko Seiki magnetically-levitated turbomolecular pump backed by an scroll pump (no oil containing pumps used in the lab)

- Additional bottom flange port for second turbopump or cryopump

- 8” CF viewport

- 10” CF multi-pin instrument electrical feedthrough flange

- Numerous available flanges at an assortment of chamber positions for electrical or vacuum feedthroughs

- High purity nitrogen available for instrument purging

- Chamber vented with high purity nitrogen

- Chamber pressure, temperature, and CAPS instrument conditions monitored remotely

- Routine base pressures of 1 x 10-7 Torr

- Reaches high vacuum (turbo starts) in 10 minutes

- No thermal control

- No TQCM, No RGA

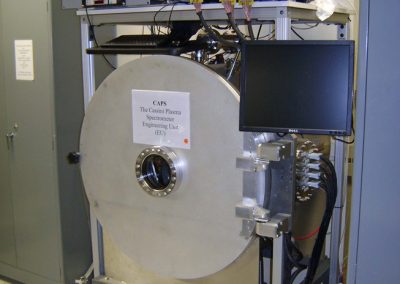

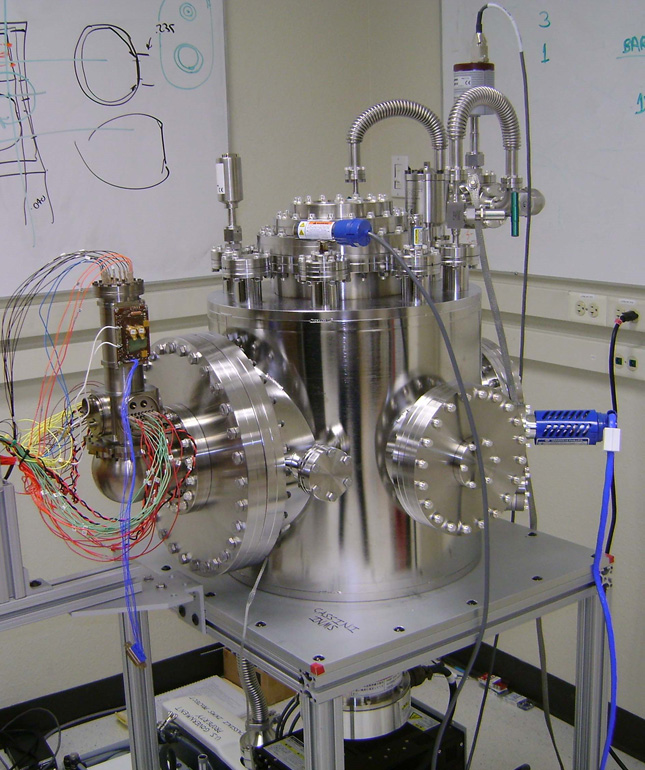

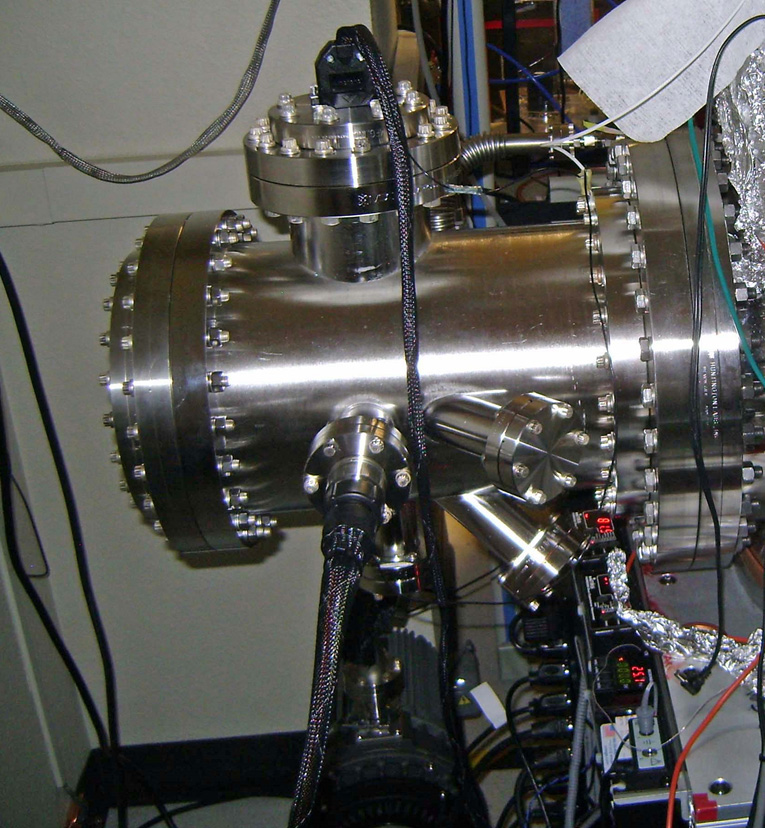

INMS Chamber Features:

- 16” x 16” stainless steel cylindrical chamber

- Three (3) 8” CF ports, two (2) 10” CF port, one (1) 13.25” CF port, and ten (14) 2.75” CF ports

- Axis of target flange (13.25” CF), all three (3) 8” CF flanges and two (2) 2.75” CF flanges occupy same horizontal plane

- Axis of target flange (13.25” CF), two (2) 10” CF flanges and one (1) 8” CF flanges occupy same vertical plane

- All metal sealed flanges and fittings

- Ceramic insulators and isolation

- NO ELASTOMERS

- Nominal base vacuum level 3 x 10-10 Torr after 200C bakeout

- INMS instrument bakeable to 250C

- Chamber bakeable to 400C, but limited to program, mission, science instrument, ion gun and turbopump temperature considerations

Cassini Ion & Neutral Mass Spectrometer Calibration Chamber

INMS Schematics

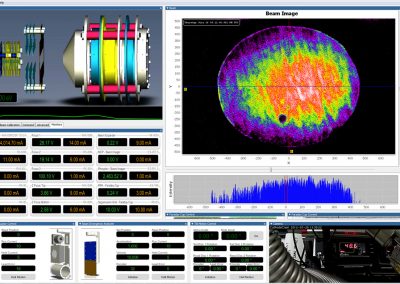

INMS Chamber Features (cont):

- INMS gimbal motion control (+/- 10 degrees in any plane)

- Scriptable movement, ion gun and instrument control

- Instruments or detectors up to 13.25” CF size

- Automated chamber parameter control, monitoring and recording

- Hardware and software overpressure failsafe protection mechanisms for system and mission critical flight hardware

- PC-controlled HV power supplies for up to 30 ion lens elements

- Four (4) automated filament emission regulator power supplies for operating up to four (4) ionization sources

- Flight-qualified RF power supply for quadrupole rod operation

- Two (2) Granville-Phillips Stabil-Ion® gauges for pressure measurement and vacuum interlock operation from 1×10-4 to 1×10-10 Torr range

- MKS spinning rotor gauge transfer standard for precise NIST-traceable pressure measurements from 1×10-2 to 1×10-7 Torr operation

- Two (2) Granville-Phillips Convectron® gauge for turbopump foreline monitoring and main chamber during venting and initial evacuation

- Pfeiffer PrismaPlus quadrupole mass spectrometer (QMS) residual gas analyzer (RGS)

- No TQCM

- No clean room or tent

- < 1 hour to reach 1×10-6 Torr, 3×10-10 Torr typical after bakeout

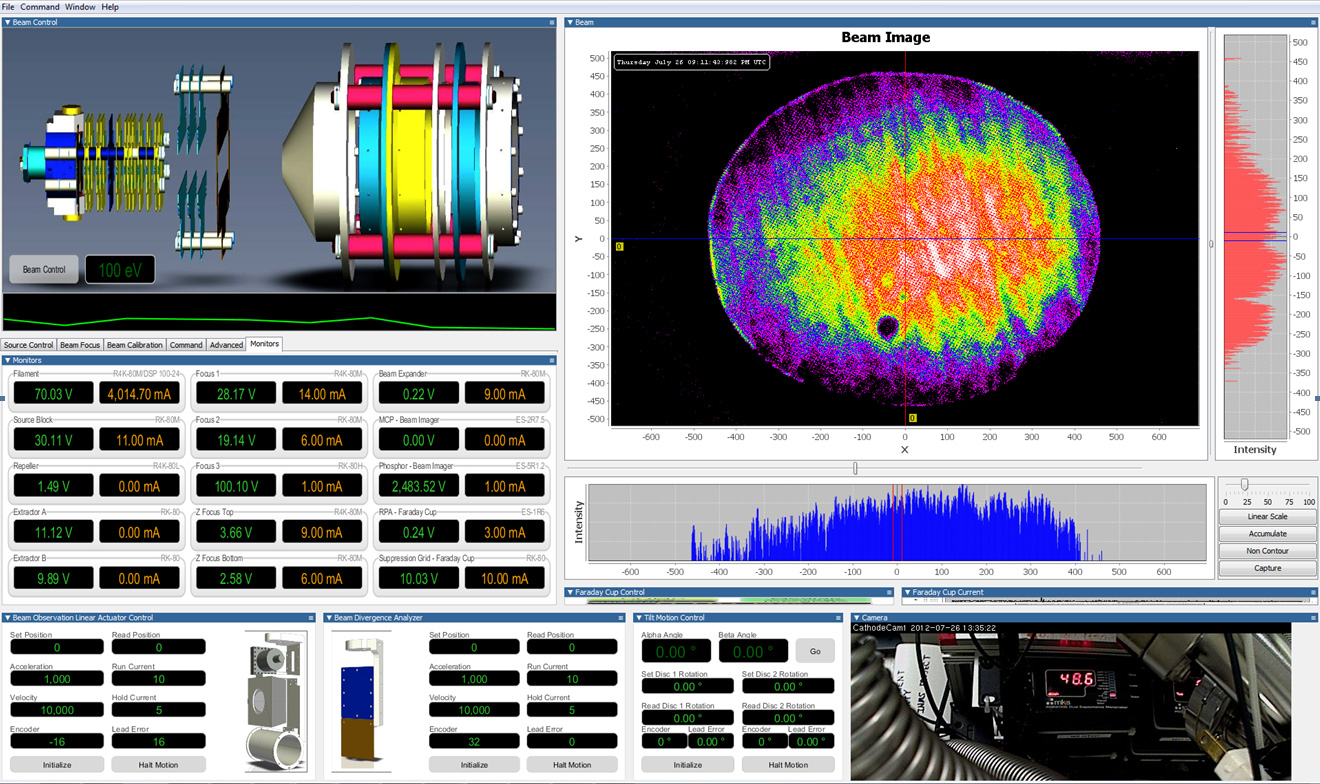

Ion Source

- Nominally supplies 5 ion species H+, Ar+, Ne+, He+, N+ and ion species relevant to Cassini mission, but other species possible

- Ion energies from 1 keV down to < 10 eV

- MCP imaging detection system

- Faraday cup detection and beam monitoring system

- Ion optics for beam spreading at target

- Internal ion apertures for beam diagnostics and focusing

- SwRI-developed custom ion source

- Drift tubes for conducting ions to target at low eV

- Ion source-to-target distance: ~30”

Cassin INMS Calibration System Ion Gun

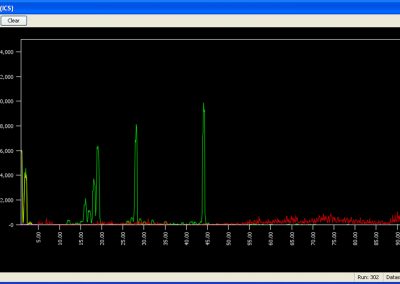

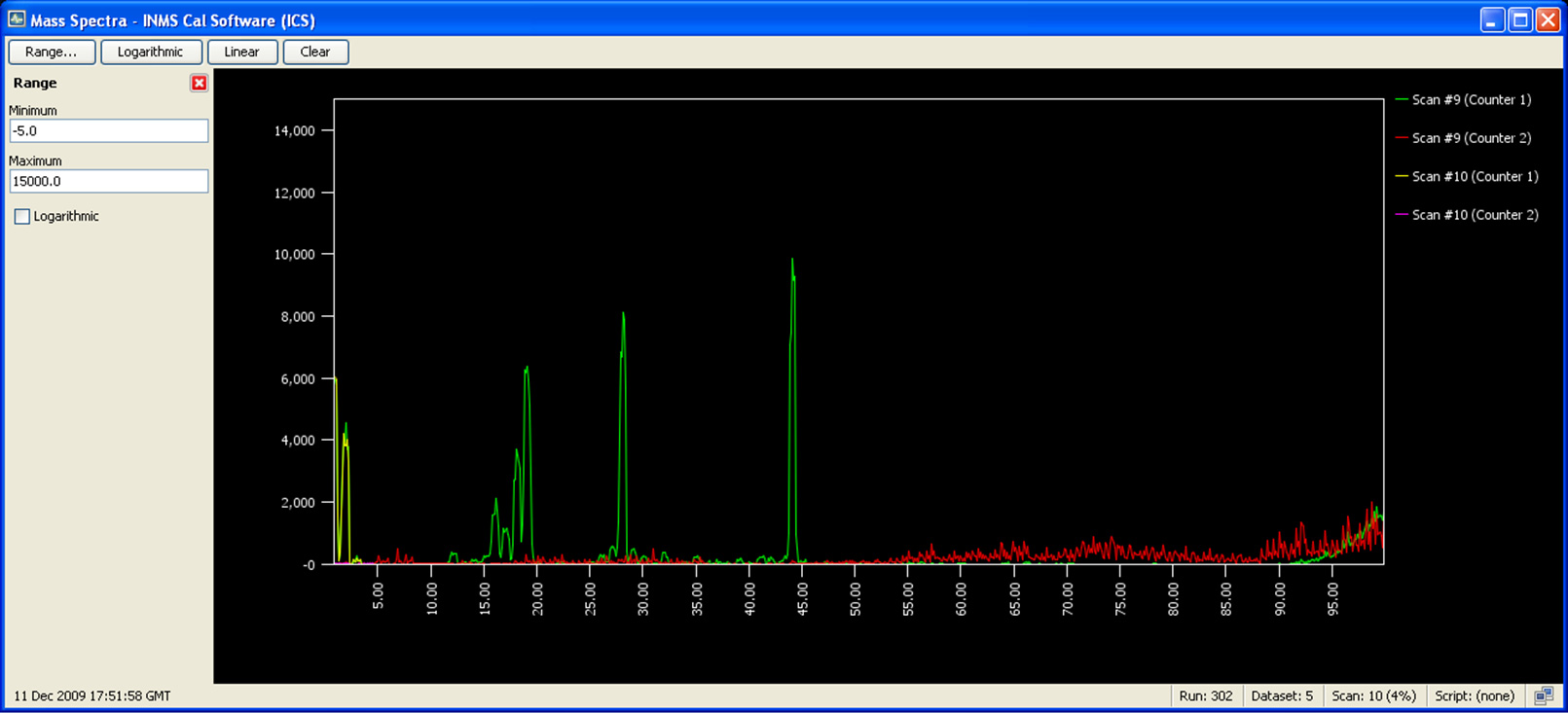

Sample INMS mass scan

Graphical User Interface (GUI) for ion gun operation

Materials prohibited in both ion gun and main chamber: nylon, silicone, PVC, low molecular weight hydrocarbons, zinc, cadmium, brass, particulate contaminated or producing items/mechanisms (blacklight inspection prior to chamber entry preferred).