Instrument Development and Calibration Laboratory

A 1680 square foot temperature and humidity controlled laboratory with 189 square feet of cleanroom space.

[printfriendly]

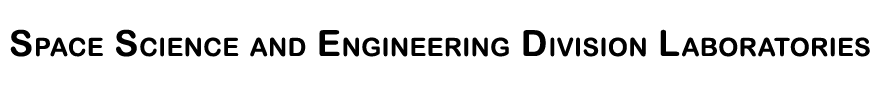

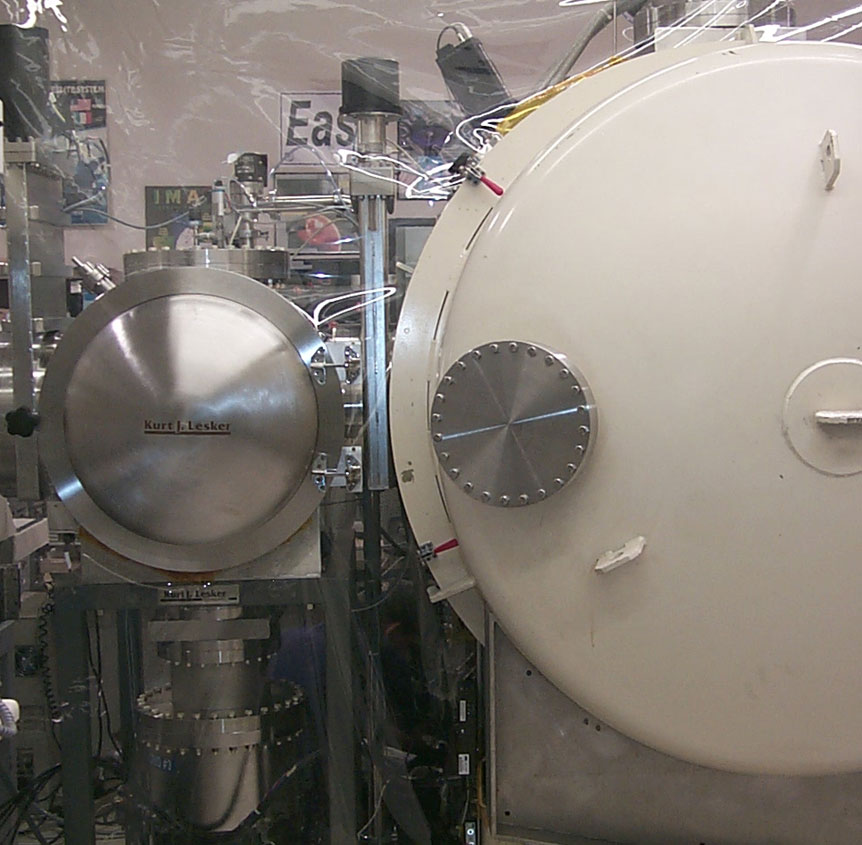

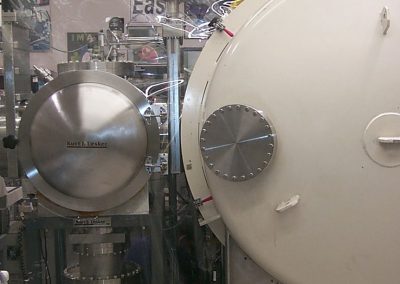

Ion Chamber

- Chamber door opens into a class 10000 clean tent.

- Laminar flow hood (class 100) with ESD monitoring in the cleanroom area.

- Main Ion Chamber Dimensions: 48” x 84”

- System pumping: 2 Cryo-Torr 10’s (3000l/s pumping speed), Dry scroll pumps, Turbo pumps (400l/s and 1000l/s) (no oil containing pumps used in the lab)

- Numerous available flanges at an assortment of chamber positions for electrical feedthru’s.

- High purity Nitrogen available for instrument purging

- All chamber venting done with high purity nitrogen

Ion chamber configuration

Main chamber environment diagnostics/monitoring include:

- Equipped with an Ametek 200AMU RGA

- Positioning system parameters

- Pressure and temperature

- Chamber interior monitored by webcams

Nominal main chamber performance:

- Routine base pressures of <1 x 10-8 Torr

- Reaches cross-over point in 42min

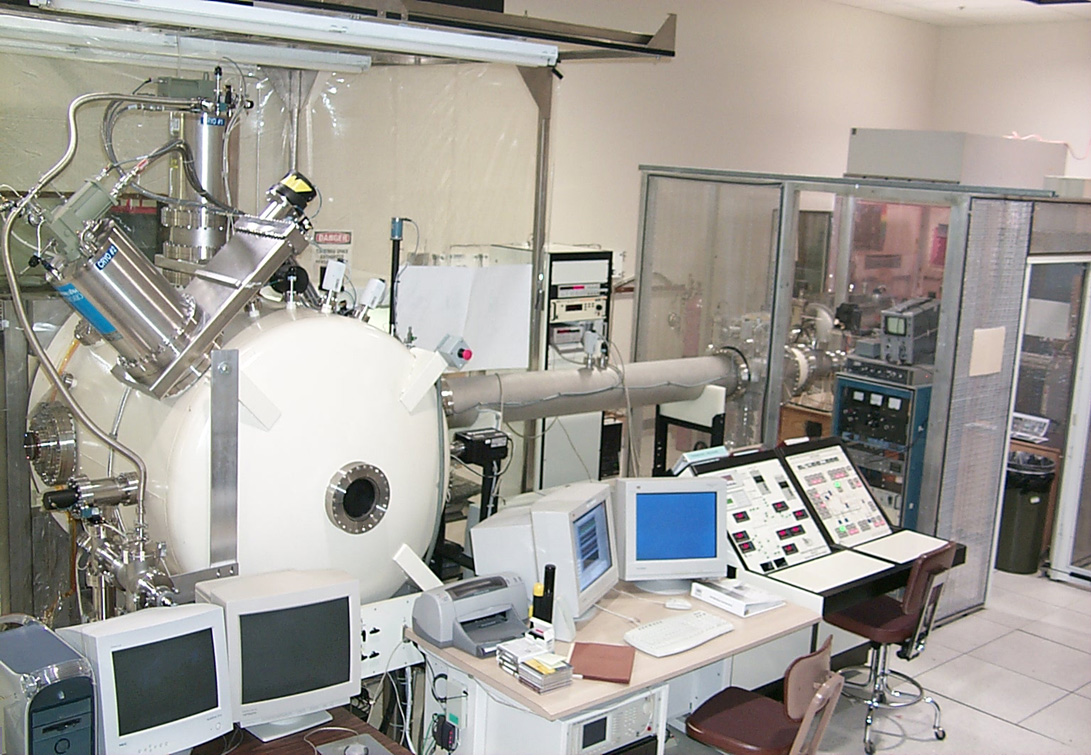

Ion Chamber Positioning System

- Four degrees of freedom

- Scriptable movement

- Instruments up to 25kg and 70cm x 90cm

- Automated chamber control and parameter monitoring and recording

- Built in failsafe mechanisms to protect mission critical flight hardware

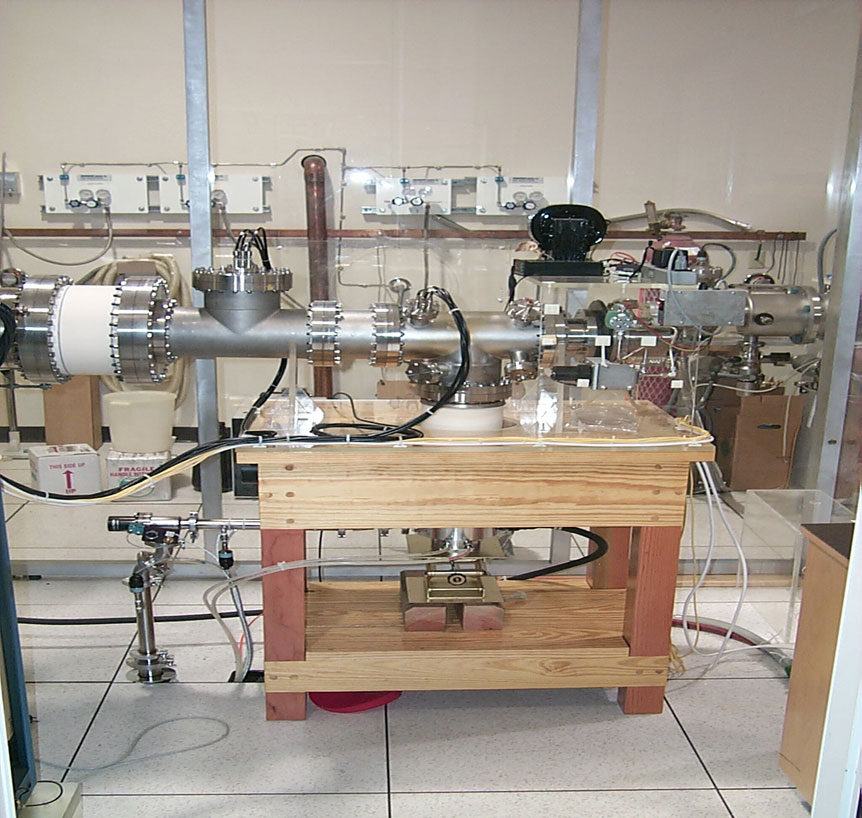

Science Chamber 18″ x 30″

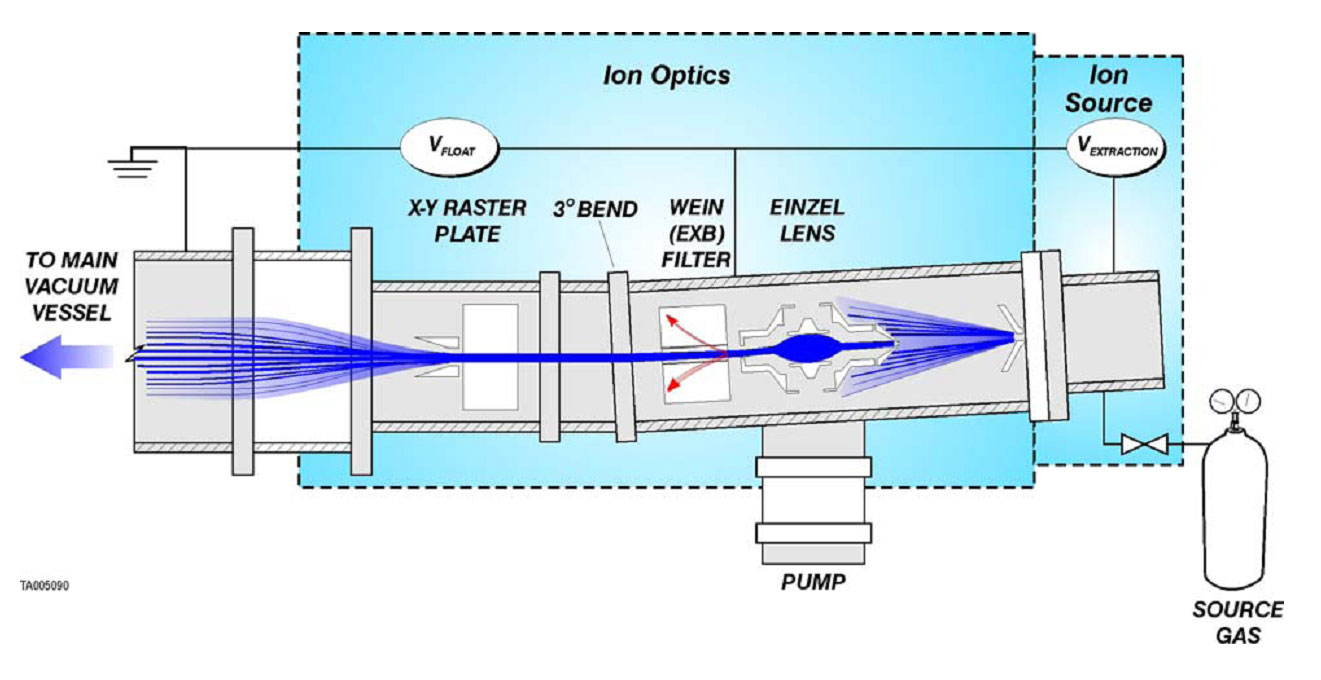

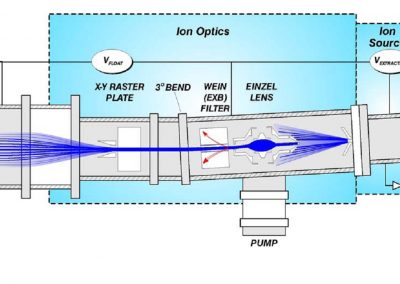

Ion Source and Electro-optics Schematic

- Nominally supplies 5 ion species H+, Ar+, Ne+, He+, N+ other species possible.

- Ion energies up to 50KeV

- MCP imaging detector Quantar model 3398A and ABM available for beam diagnostics

- Peabody Scientific Model PS-100 Duoplasmatron Ion source

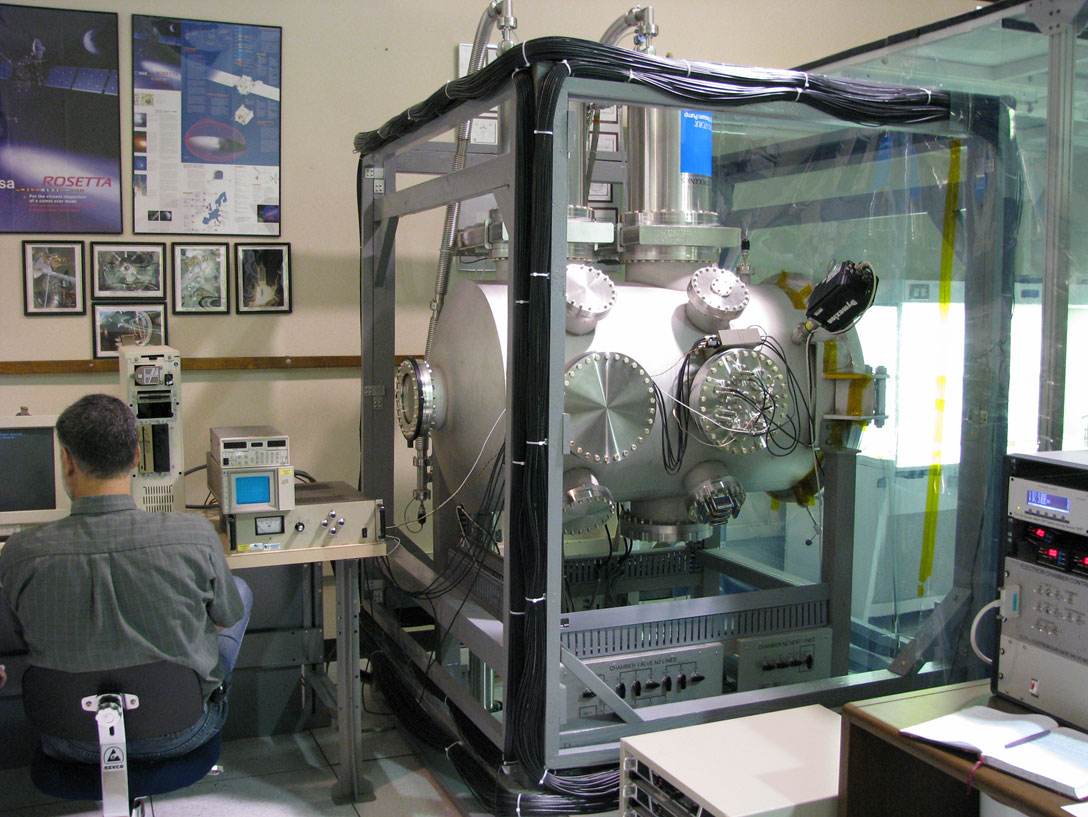

Electron Chamber 49″ x 35″

- Door opens into a class 10000 cleanroom

- Laminar flow hood class 100 with ESD monitoring for instrument build and modification in the cleanroom area.

- Equipped with a Kimball Physics 30kV electron gun

- Helmholtz coils surround the chamber.

- Two cameras monitor the chamber interior.

- Numerous available flanges at an assortment of chamber positions for electrical feedthru’s.

- System Pumping: 2 Cryo-Torr 10’s (3000l/s),dry scroll pumps

Chamber environment diagnostics/monitoring include:

- Equipped with an Ametek 200AMU RGA

- Positioning system parameters

- Pressure and temperature

- Chamber interior monitored by webcams

Nominal chamber performance:

- Routine base pressures of low 10-8 Torr

- Reaches cross-over point in ~12mins

Electron chamber positioning system

- 3 degrees of freedom

- Automated chamber control and parameter monitoring and recording

- Built in failsafe mechanisms to protect mission critical flight hardware

Materials prohibited in both Ion and Electron chambers: nylon, silicone, PVC, low molecular weight hydrocarbons, zinc, cadmium, brass, particulate contaminated or producing items/mechanisms (blacklight inspection prior to chamber entry preferred)

Jacob Grimes is responsible for the Instrumentation Development and Calibration Facility in the Space Science and Engineering Division at Southwest Research Institute. This facility is used in the testing and calibration of prototype and space flight instrumentation.

Mr. Cronk is NASA certified in soldering, staking and cable harnessing and has extensive experience in the design, maintenance, and operation of UHV equipment and systems.